Experimental-numerical study of laser-shock-peening-induced retardation of fatigue crack propagation in Ti-17 titanium alloy - ScienceDirect

Laser Shock Peening on Zr-based Bulk Metallic Glass and Its Effect on Plasticity: Experiment and Modeling | Scientific Reports

Metals | Free Full-Text | FE Analysis of Laser Shock Peening on STS304 and the Effect of Static Damping on the Solution

Evaluation of laser shock peening process parameters incorporating Almen strip deflections - ScienceDirect

Enhancement of rolling contact fatigue performance of ferrite–pearlite steel with laser shock peening - Yang Zhang, Qinglin Lian, Xi Wang, 2019

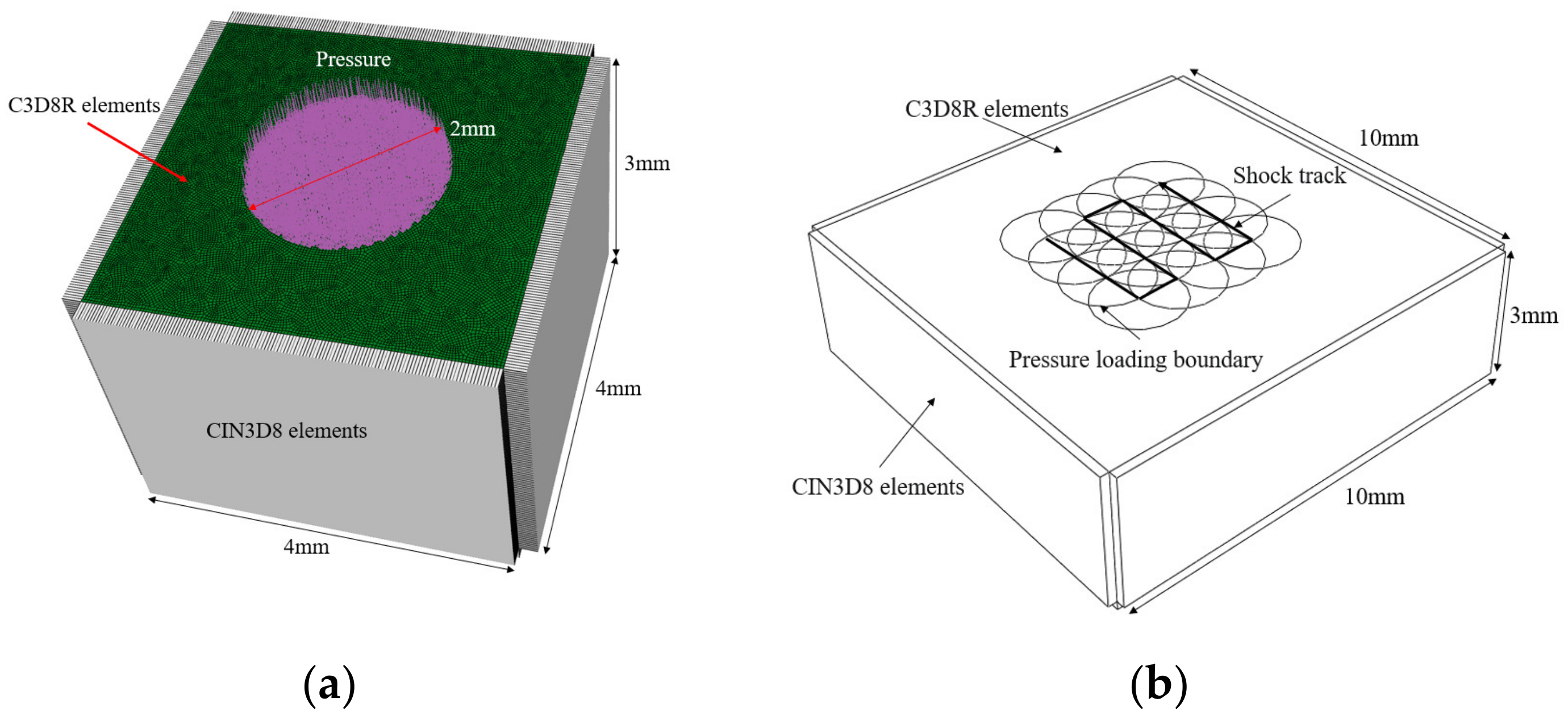

Effects of Simulation Parameters on Residual Stresses in 3D Finite Element Laser Shock Peening Analysis | Semantic Scholar

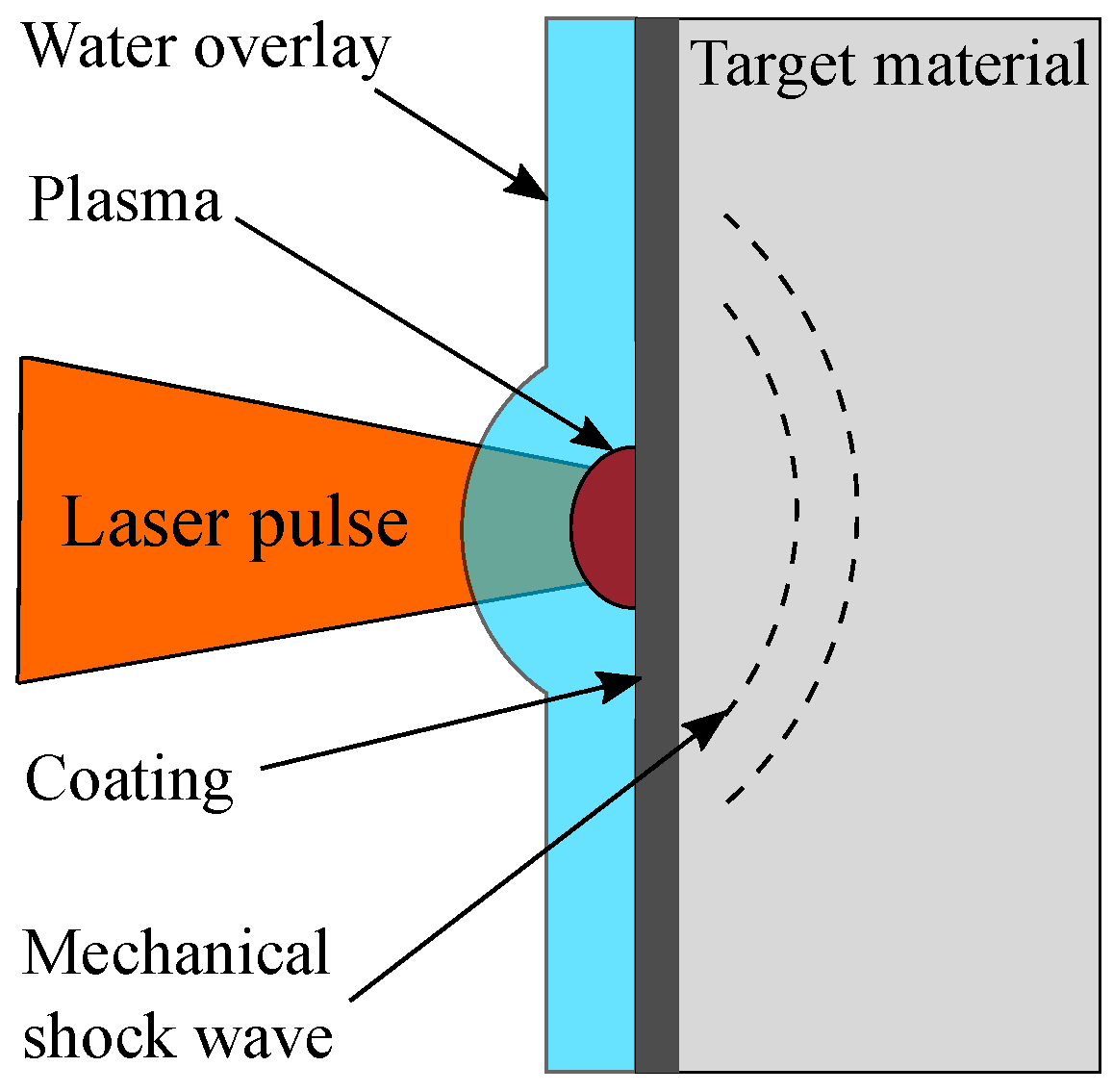

Metals | Free Full-Text | Coupled Modeling Approach for Laser Shock Peening of AA2198-T3: From Plasma and Shock Wave Simulation to Residual Stress Prediction

Materials | Free Full-Text | Numerical Simulation on Laser Shock Peening of B4C-TiB2 Composite Ceramics

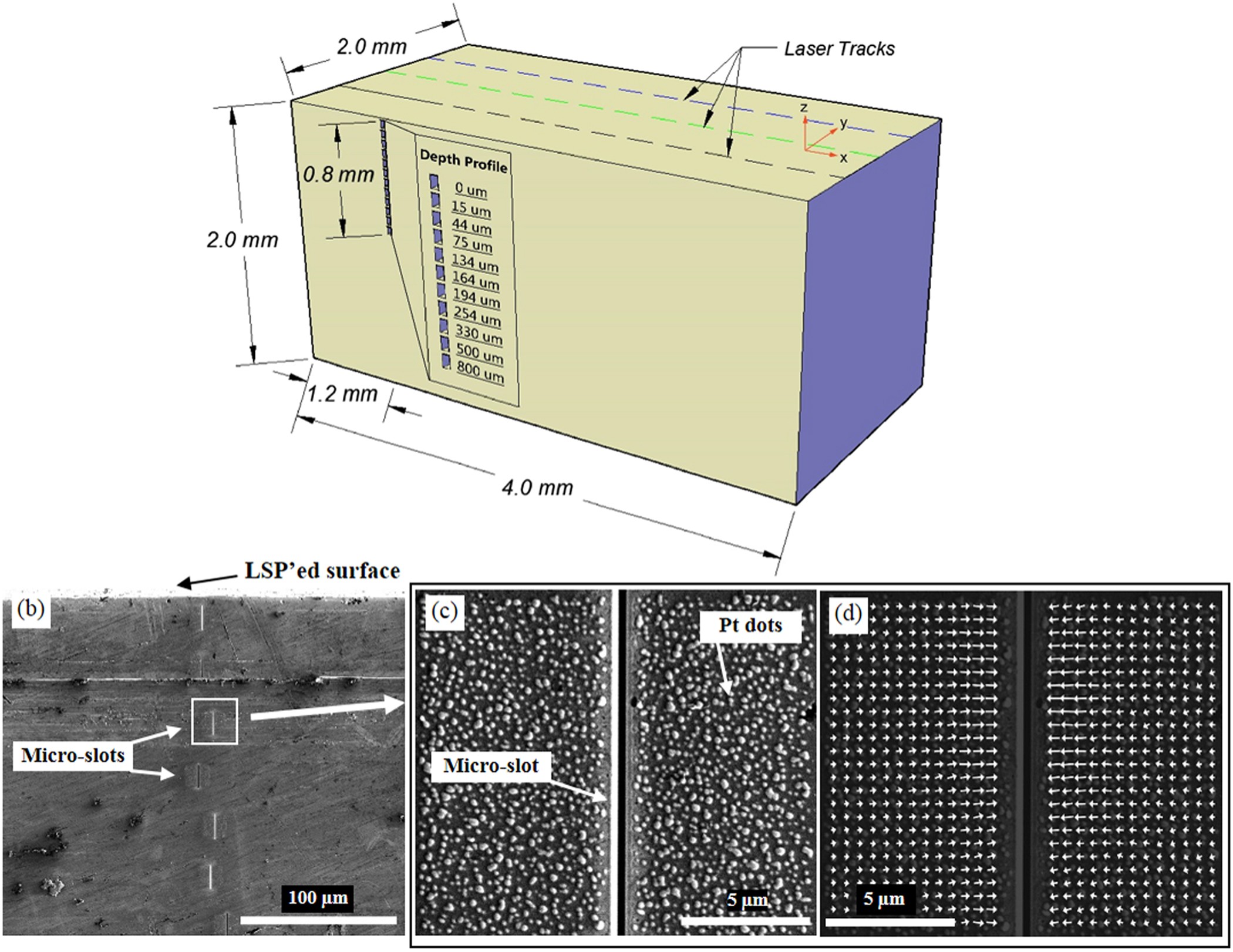

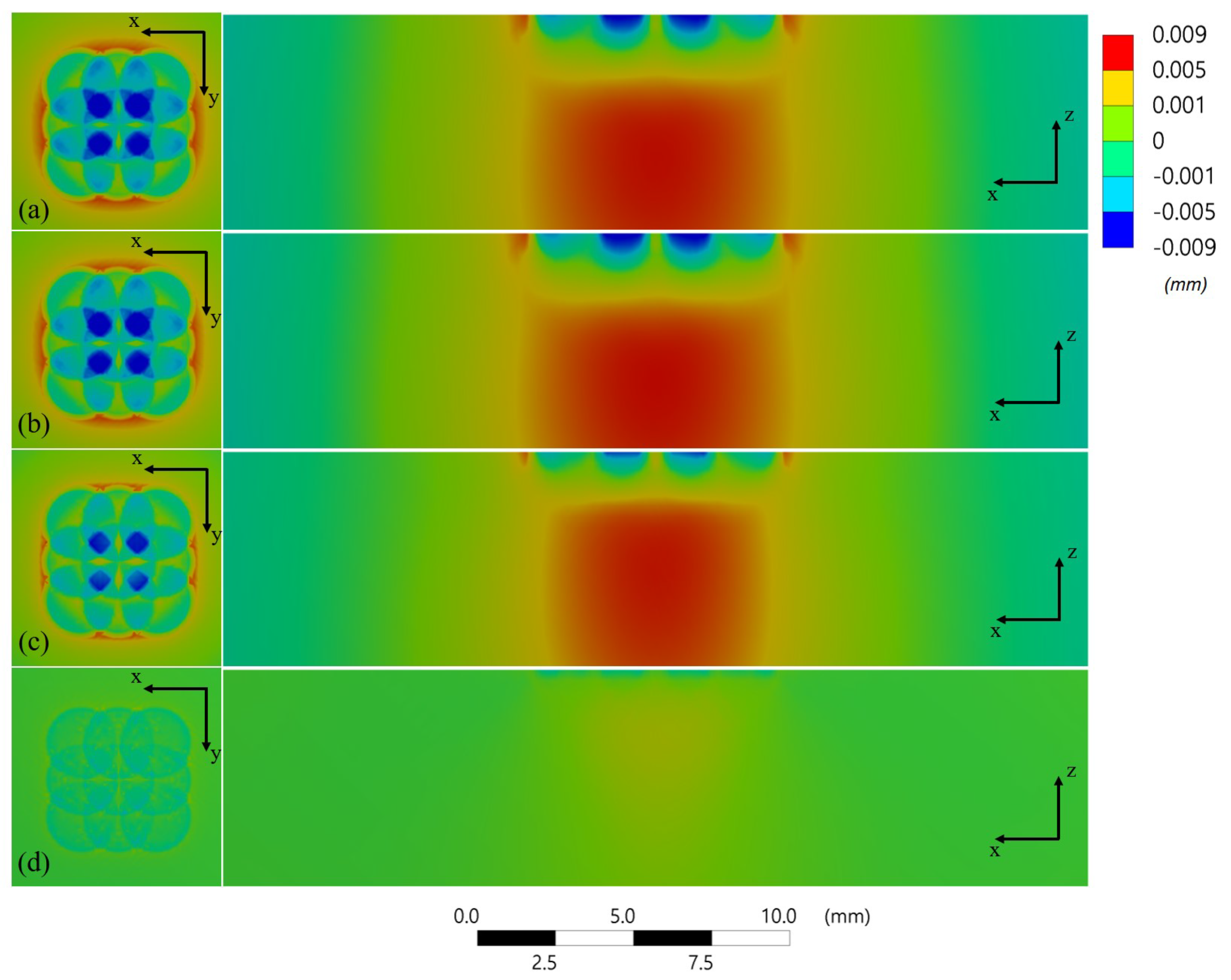

Influence of laser shock peening on the residual stresses in additively manufactured 316L by Laser Powder Bed Fusion: A combined experimental–numerical study - ScienceDirect

Figure 1 from Author ' s personal copy Massive parallel laser shock peening : Simulation , analysis , and validation | Semantic Scholar

Amazon.com: Laser Shock Peening: Performance and Process Simulation (Woodhead Publishing Series in Metals and Surface Engineering): 9781855739291: Ding, K, Ye, L: Books

Metals | Free Full-Text | The Effect of Laser Shock Peening on the Corrosion Behavior of Biocompatible Magnesium Alloy ZK60

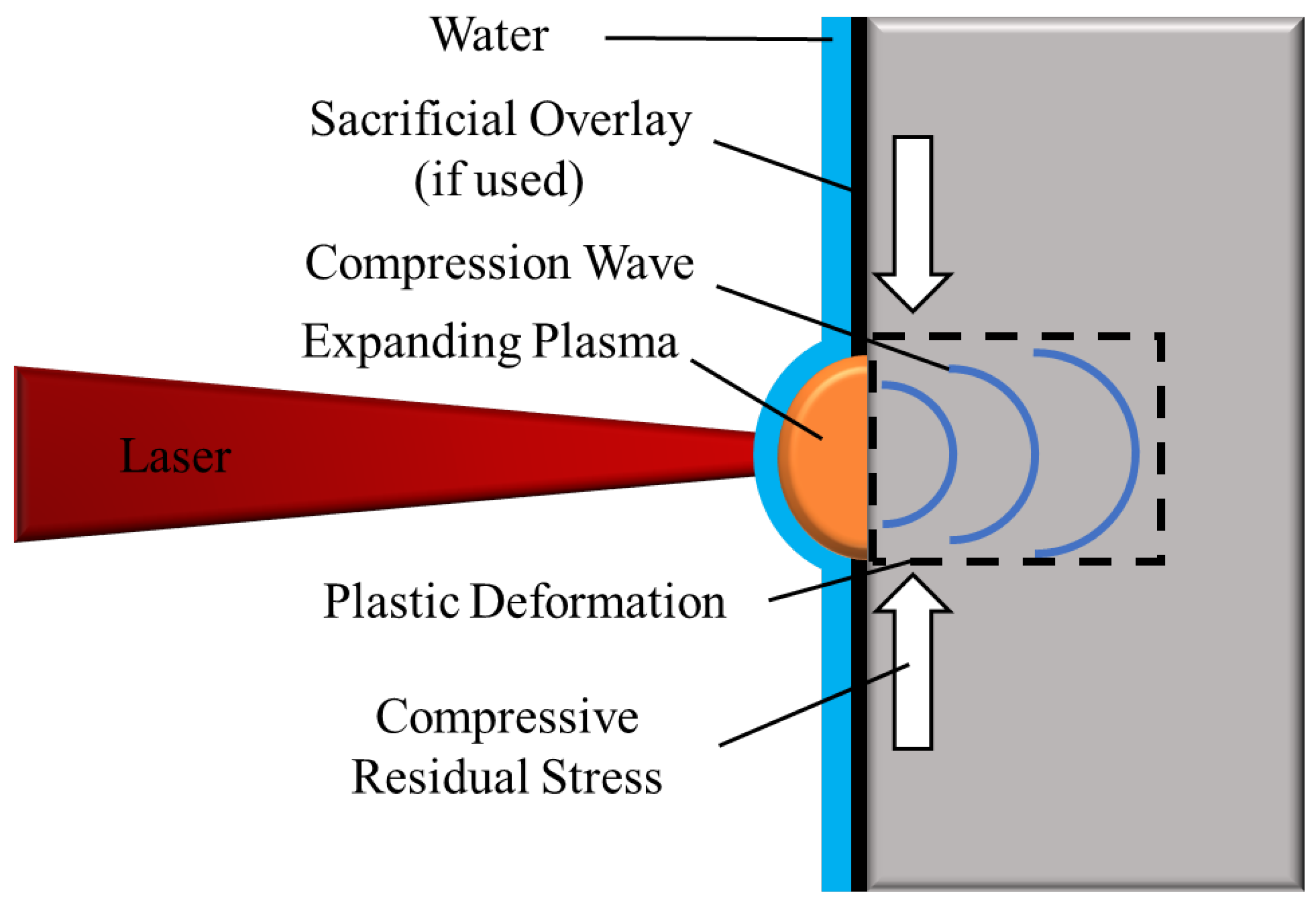

![Process of laser shock peening without coating [8]. | Download Scientific Diagram Process of laser shock peening without coating [8]. | Download Scientific Diagram](https://www.researchgate.net/publication/273315328/figure/fig1/AS:294944708284420@1447331706657/Process-of-laser-shock-peening-without-coating-8.png)